Precision Performance Tuning & Installation

This end of the business is where it all comes together! Call this the “Z” in the A-Z process. All of the planning and preparation gets showcased in the final product. This is where the term “Performance” is measured in the form of Results! What really goes on here? Below is a good list of the tasks performed at our final stage!

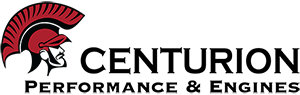

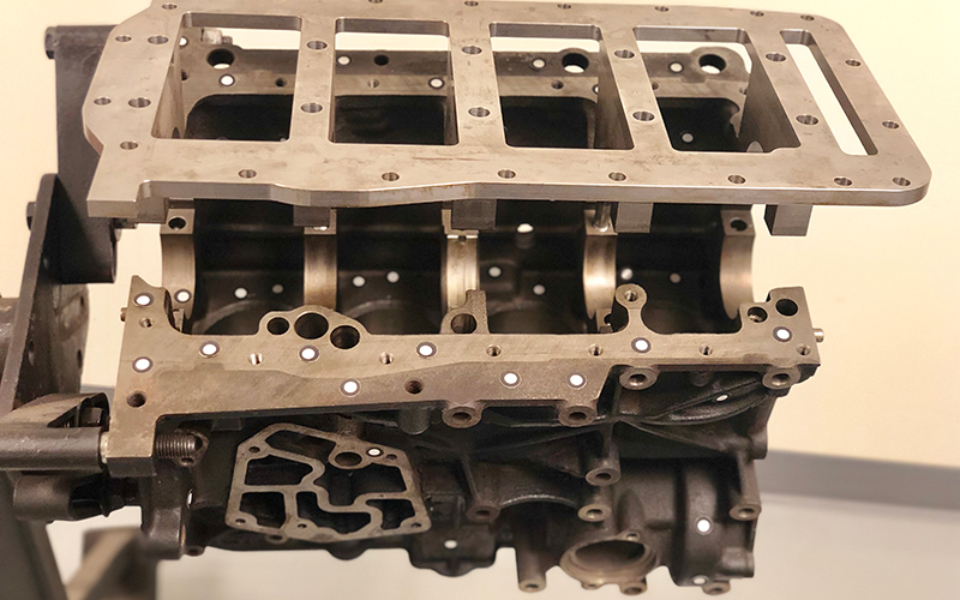

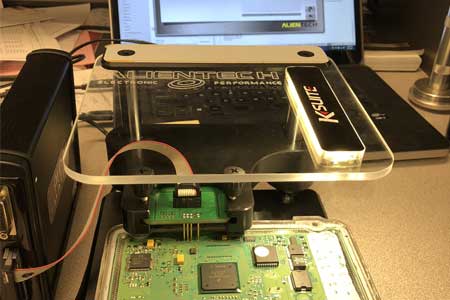

Performance Tuning: Factory cars and trucks leave a lot on the table for increasing performance. We work with various Tuners across the country of whom we’ve built a relationship based of customer service and results. These individual tuners have been selected over the years for their capabilities with different platforms such as, Ford Powerstroke, Chevrolet Duramax, Dodge Cummins, Volkswagon/Audi TDI, BMW, Mercedes CDI and many more! These are not limited to diesels either! Chrysler HEMI, GM LS series, Ford Coyote and Modular, Turbocharged, Supercharged or Normally Aspirated setups are all applicable. Road testing, Dyno testing and data logging is typical in this process so we can verify the results of the new combination of 0’s and 1’s being programmed into your vehicles modules.

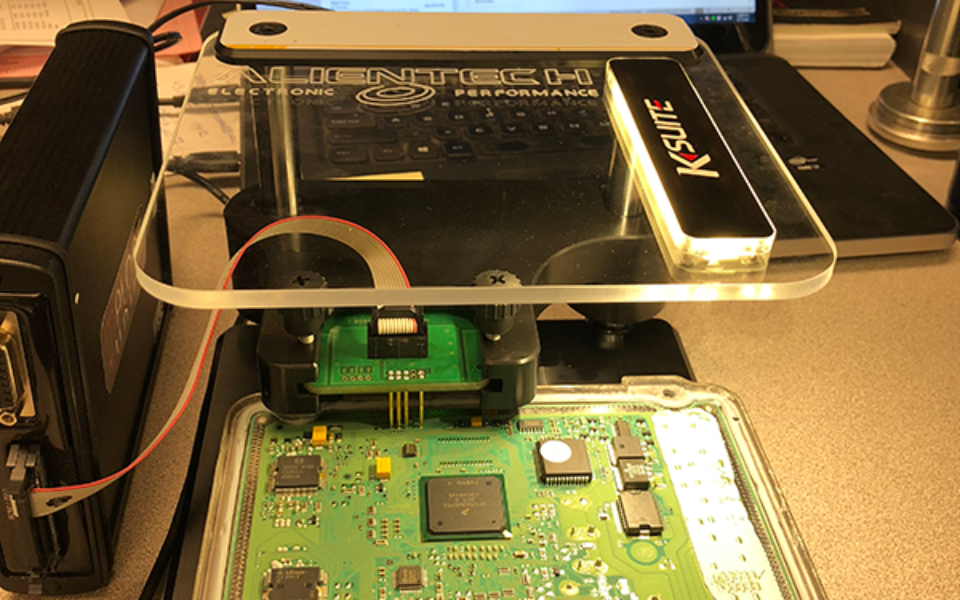

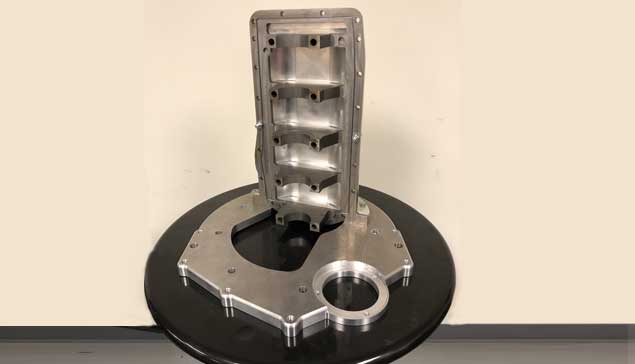

Supporting Modifications Install: This is a diverse grouping that encompasses anything that will be altered to your vehicle to enhance it’s performance. This can be upgrading Turbochargers, Fuel injectors, intake and exhaust components, Valvetrain upgrades. This can be suspension and brake upgrades or a different slick set of wheels and tires. Gauges for monitoring vehicle parameters in the car, upgraded fuel systems to handle the volume fuel demands in your performance application are just a small set of examples of what goes into supporting modifications.

Custom Fabrication: Often times when bringing many supporting modifications together in one application, they don’t always work well together. This demands flexibility and changes to components or systems to make them all work in unison. This could be a custom stainless steel exhaust system to clear the new suspension, or incorporate exhaust cutouts that allow you to cruise down the road quietly.

Final Assembly: All of our custom builds will end up here to get wrapped up and prepared for the road. This includes a perfect wheel Alignment utilizing our state-of-the-art Hunter Hawkeye Elite Alignment rack. We often set vehicles to factory specifications or custom specifications based on application. You wouldn’t want to use factory specs on a Modernized Classic car with rack and pinion steering and modern suspension, and we certainly don’t! All custom builds have tailored alignments to fit the mission of the vehicle. The final assembly stage includes shake-down road tests. We don’t want you getting 50 miles down the road only to have an annoying exhaust rattle or small fluid leak. This stage is really where the acute eye comes into play. It is our goal to leave you with a great feeling of pride and confidence in the product we’ve put so much time, energy and passion into.

So much thought and time goes into each project we do, whether it’s a simple tune or full custom build with one of our exquisite engines. This is what we do. We enjoy the work we do and enjoy even more, the relationships and experiences we build with customers along the way. We look forward to the opportunity to work together, as well as the car shows, cruise nights, drag strips and truck pulls to see our work in action!